-40%

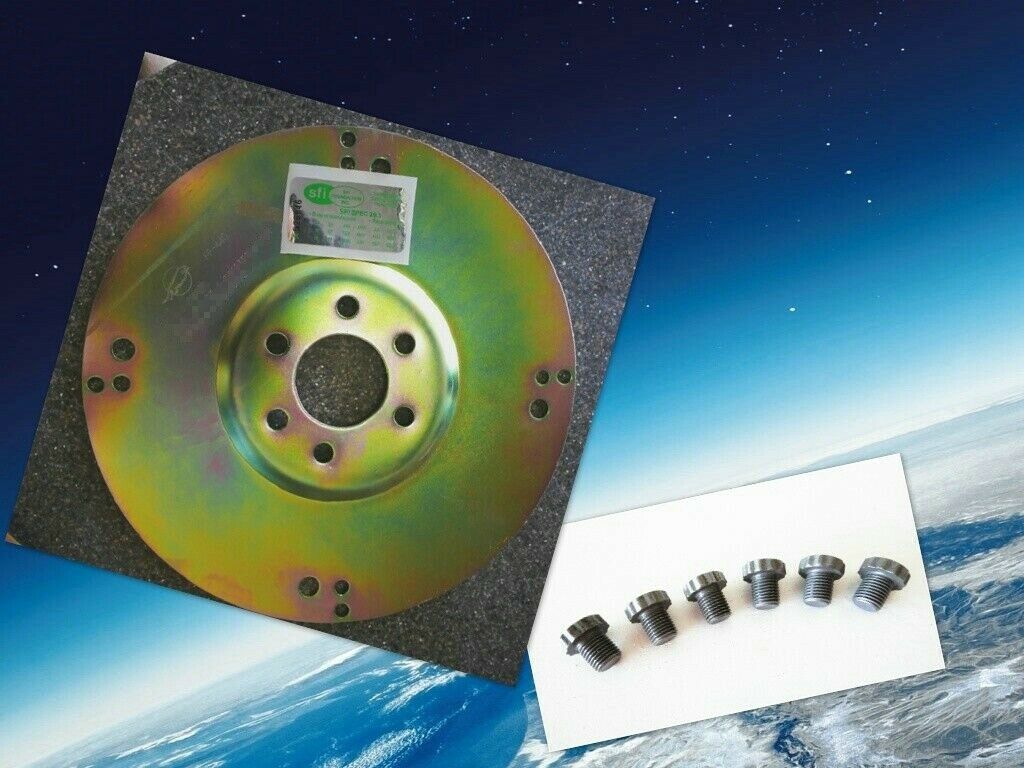

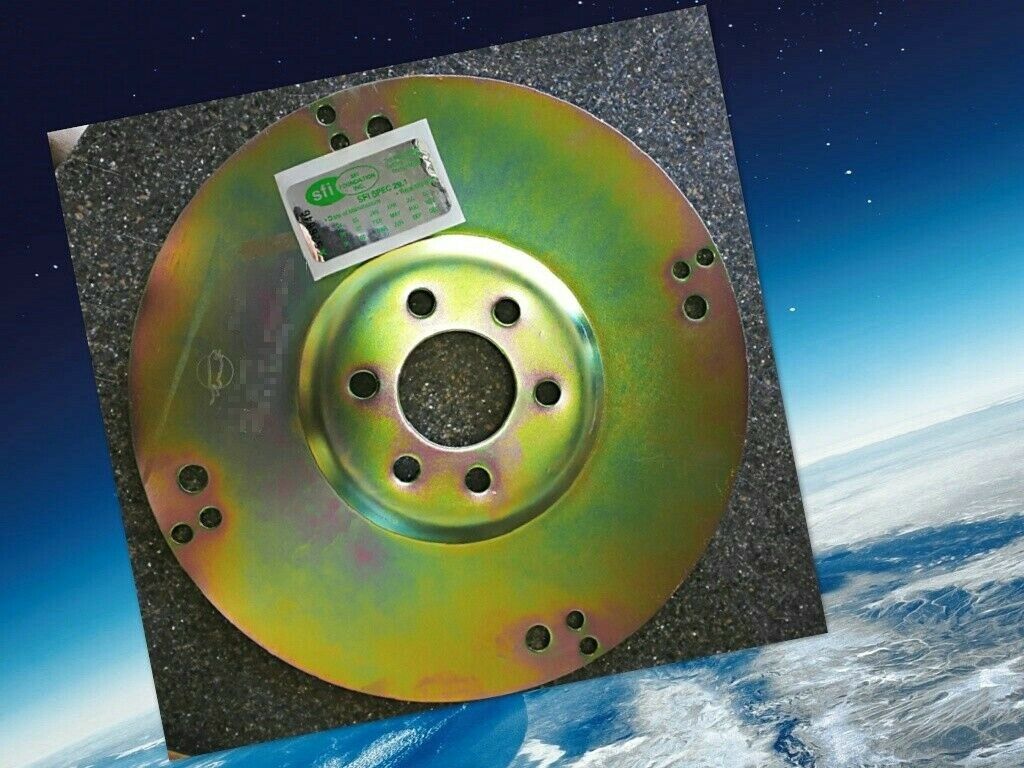

MFactory BMW E8X 135i MT 2006-2008 8-Bolt 21lb Single Mass Chromoly Flywheel

$ 263.97

- Description

- Size Guide

Description

- MFactory BMW E8X 135i MT 2006-2008 8-Bolt 21lb Single Mass Chromoly Flywheel -*** You are purchasing

directly

from MFactory Competition Products,

not

a reseller ***

Includes:

- FREE Worldwide Shipping

OVERVIEW

Achieve increased throttle response and acceleration with the MFactory range of single-piece Lightweight Flywheels .

Diamond Cut to exacting tolerances from Forged Chromium-Molybdenum Steel

Perfect fitment & finish ensures hassle-free installation

Designed using leading-edge Solidworks 3D CAD & Cosmos FEA software

Advanced Geometry minimizes parasitic drivetrain losses. Race transmissions built with MFactory components transfer, on average, 1-2% more power to the ground over our competitors!

Precision Balanced to over 12000rpm

Ensures the utmost reliability from our Lightweight Flywheels, which are specifically designed to reduce weight and inertia for improved engine response and acceleration

SPECIFICATIONS

Made from imported Japanese SAE 4140 Steel

Forged, Double Tempered and Super Sub-Zero treated for unsurpassed toughness

Proprietary Nitride surface treatment for increased surface hardness

COMPANY PROFILE

Established in 2004, MFactory Competition Products has since grown to become one of the Leading Global Manufacturers of high performance

off-the-shelf

aftermarket transmission components, with our large range of

Forged

Final Drive Gears, LSD's and Close Ratio Gears offering enthusiasts undeniably

THE

most

cost-effective

method of performance improvement, far surpassing that of conventional engine tuning.

Being a specialist in this industry requires focused knowledge that can only be gained through years of first-hand testing and tuning experience. Challenging the old adage that

'there is no replacement for displacement'

, MFactory Competition Products have become a prominent figure in the highest levels of Motorsport, with class-leading recognition the world over in Circuit Racing, Drag Racing and Rally.

Every product within the MFactory catalog is designed

in-house in the USA

and manufactured

in-house

to our own specifications at both our US R&D Facility and our

multi-million dollar, state-of-the-art, ISO Regulated

Taiwan factory, before being tested & developed in the real-world on state-of-the-art race vehicles from North America, Europe and Asia-Pacific. Our products are designed from the beginning to surpass the competition.

Why choose MFactory?

Here's why:

Some of our companies most noted achievements include (but not limited to):

Official OEM to Honda of America's Motorsports Divisions

World's Largest Manufacturer of Forged Performance Transmission Components for Japanese and European Automobiles

North America's Largest Manufacturer of Limited Slip Differentials for Japanese and European Automobiles

North America's Largest Honda/Acura Performance Transmission Specialist

The World's Only Performance Transmission Manufacturer to offer a 30 Day Money Back Guarantee!

The World's Only Performance Transmission Manufacturer to offer a Discounted Trade-in for a Competitors Product; even if it's damaged!

Design:

Use of the latest Solidworks 3D CAD & Cosmos FEA software alongside our own proprietary gearing tools & equipment

Advanced gear geometry helps to increase tooth strength, reduce friction and minimize parasitic drivetrain losses

Carefully chosen gear ratios to maximize performance for any situation

Manufacture:

All of our Bar Stock is imported from Japan to ensure the purest steel grades

- SAE 8620: Used mainly in our Final Drive Gears, with a post-treatment Tensile U/Y Strength of over 900/550 MPa and HRC 61

- SAE 4320: Used mainly in our Close Ratio Gears, LSD's and Axles, with a post-treatment Tensile U/Y Strength of over 1100/700 MPa and HRC 62

- SAE 9310: Used mainly in our PRO Series Gears, with a post-treatment Tensile U/Y Strength of over 1300/850 MPa and HRC 62

All MFactory components are

Forged

. We do not use

inferior

Cast or Billet processes

- Forged components are upto 30% stronger & tougher than the equivalent 'Billet' component. Click

here

for details

Advanced material processing, heat treatment & finishing techniques offer superior strength, durability and quality

- Primary Heat Treatment: After the forged parts come off the press, they are Normalized and Annealed to relieve residual stresses and make them machine workable

- Machining: After the forged blanks are completed, we use Industry-leading Multi-Axis CNC and CAM equipment to machine the parts

- Secondary Heat Treatment: State-of-the-art Case Hardening procedure achieved via computer-controlled Gas Carburization and Quenching

- Double-Tempering: A superior heat treatment technique used to decrease the brittleness and increase the toughness of our parts

- Surface Grinding: Through the use of our state-of-the-art diamond grinding machines, we ensure all parts are smooth, precise and free of burrs

- Super Sub-Zero Processing: An advanced treatment technique whereby the parts are cryogenically hardened at -300°F, realigning the steels crystalline structure for maximum strength, then heat tempered again for a 3rd time to ensure maximum toughness (resistance to fracture)

- Micro-Peening: Our final treatment stage, the parts are subject to a high speed shot blast with our proprietary micro media, creating a super smooth surface

- 3-Stage Ti-Moly Nano-Peen Process: For our PRO Series parts, instead of our regular Micro-Peening process, the parts are subject to hyper-velocity bombardment with our proprietary Ti-Moly nano media, creating a highly-compressed, self-lubricating outer surface which reduces friction by 30%!

Quality Control:

ISO Regulated, multi-level quality control procedures ensures only the best products

State-of-the-art TESA and Osaka Seimitsu Kikai Gear Measuring Equipment for extreme precision

Strict Test Protocols, including extreme durability testing on our in-house transmission dynamometer,

ensure

the MFactory Difference

Logistics:

All items in our catalog are

'Off-the-shelf'

, ensuring zerosupply delays

Multi-National Company, with offices in the UK, USA, South-East Asia and Australia

Broad Distribution Network with strategically placed Installers and Key Distributors

All products in our catalog are race-proven and are developed specifically

For Race Use Only

. We take pride in and stand by the quality of the products we offer; all of which have extensive R&D work before being released to market. Take comfort in the fact that our products are manufactured under the strictest of quality controls.

No matter what upgrades you wish to make with your pride & joy, be it a fast-road car or a fully-built track car, we have the technical knowledge to ensure any purchases you make will compliment your setup as it is backed with our extensive professional advice.

PAYMENT INFORMATION

We accept the following payment methods:

- PayPal (Verified Accounts Only)

SHIPPING INFORMATION

We offer FREE shipping on all items!

Your item will be carefully packed and dispatched within 24 hours (Mon-Fri) of receiving payment

We use UPS Worldwide Express/EMS Express delivery for all shipments

RETURNS POLICY

If you are not happy with your item please return in the original packaging and with all tags attached within 30 days. Goods must be returned carriage paid. Refund of purchase price will be refunded by the same method as the payment was made. Postage and packaging will not be refunded.

If your item is faulty or we have sent you something different to what you ordered, again please return it to us within 30 days and we will give you a full refund or replacement. Including postage and packaging.